In switch-mode power supplies (SMPS), output stability is strongly influenced by capacitor impedance and ripple current capability. Radial electrolytic capacitors used at the output stage must absorb high-frequency ripple while maintaining low internal resistance to minimize heat generation and voltage fluctuation.

For high-frequency power supplies, capacitor series such as TS13DI and D6 are commonly selected for their low impedance characteristics and improved high-frequency ripple handling. These capacitors help reduce output ripple voltage and mitigate internal heating caused by switching harmonics, especially in compact or high-density SMPS designs.

In general power and control boards, TS14, TS13DB, DC, and DE series provide a balance between impedance performance, size, and cost. These capacitors are often used where switching frequencies are moderate, but long-term stability and thermal margin are still required.

Some SMPS designs also incorporate low-leakage requirements, particularly in precision circuits or standby power rails. Series such as TS13DL and D1 are designed to control leakage current, helping maintain voltage accuracy and reducing drift in sensitive control or sensing circuits.

For audio or signal-related power sections, TS13DM is sometimes selected where stable electrical characteristics support consistent signal behavior. While not audio capacitors in the traditional sense, their predictable impedance and leakage behavior make them suitable for audio network support circuits.

Certain applications demand specialized pulse or discharge behavior, such as flash or horizontal circuits. DN and DO series address these niche requirements, where standard electrolytic capacitors may not withstand repetitive pulse stress.

A full overview of Suntan’s radial electrolytic capacitor series for SMPS and power conversion applications is available here:

https://www.suntan.com.hk/Aluminum-Electrolytic-Capacitors/Radial.html?utm_source=wordpress&utm_medium=content&utm_campaign=radial_capacitor_upgrade_20260204

When addressing SMPS instability, ripple heating, or premature capacitor failure, reviewing impedance, ripple rating, and temperature endurance together often provides the most effective improvement path. For technical consultation or product selection support, please contact us at:

https://www.suntan.com.hk/contact.html?utm_source=wordpress&utm_medium=cta&utm_campaign=radial_capacitor_upgrade_20260204

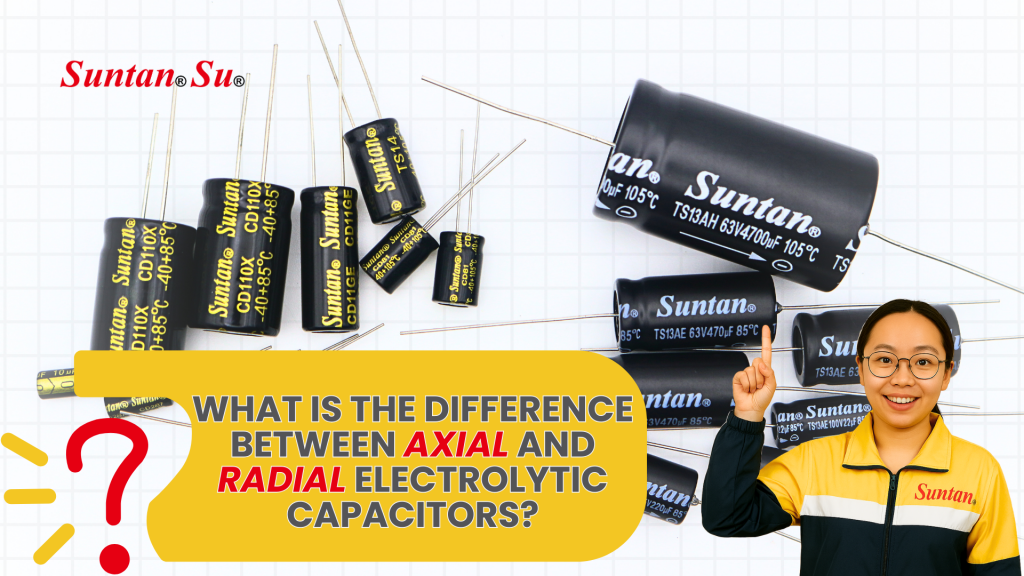

Axial vs. Radial Electrolytic Capacitors in Practical Design

In real-world circuit design, the difference between axial and radial electrolytic capacitors goes beyond lead orientation. The choice directly affects PCB layout flexibility, thermal performance, assembly efficiency, and long-term reliability.

Radial electrolytic capacitors, with both leads exiting from the base, are better suited for high-density PCB layouts and automated insertion processes. They are widely used in LED drivers, SMPS output stages, and control boards, where compact size, controlled ESR, and stable ripple handling are critical. Axial capacitors, while still useful in certain linear or mechanically constrained designs, generally offer less flexibility in modern compact power electronics.

When selecting between axial and radial types, engineers should focus on operating temperature, ripple current stress, expected lifetime, and available board space, rather than form factor alone. This is why most contemporary power and lighting designs favor radial electrolytic capacitors as the primary solution.

For a visual comparison and application overview, watch the following video:

https://www.youtube.com/watch?v=3iC4US_Hn2Q

You can then naturally follow this section with your application table or series recommendations, keeping the flow logical and engineering-driven.

For application guidance or part selection support, contact our engineering team at

info@suntan.com.hk